Designed and developed for the simulation of industrial automation process's

As part or Rockwell Automation's 2025 V18 software release, Sim3D is now referred to as Emulate3D Simulator under the new naming convention.

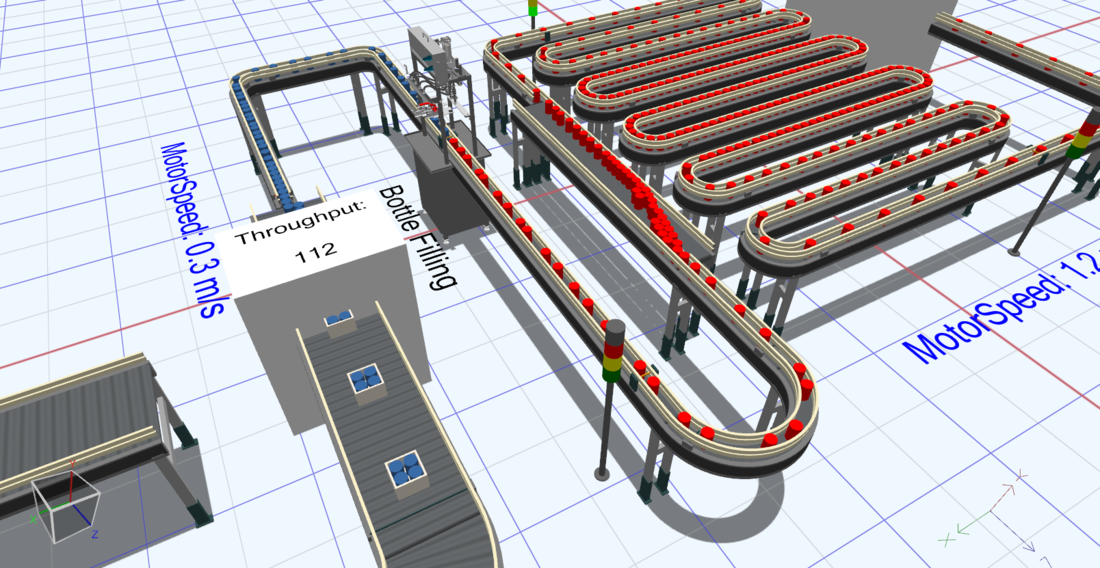

Emulate3D Simulator is a specialised 3D physics based simulation package from the Emulate3D software range. Emulate3D Simulator has been designed and developed for the simulation of industrial automation process's such as those typically found within Manufacturing, Materials Handling, Logistics, Airports, Conveying, Palletising & Packaging, custom engineering and Robotic Automation.

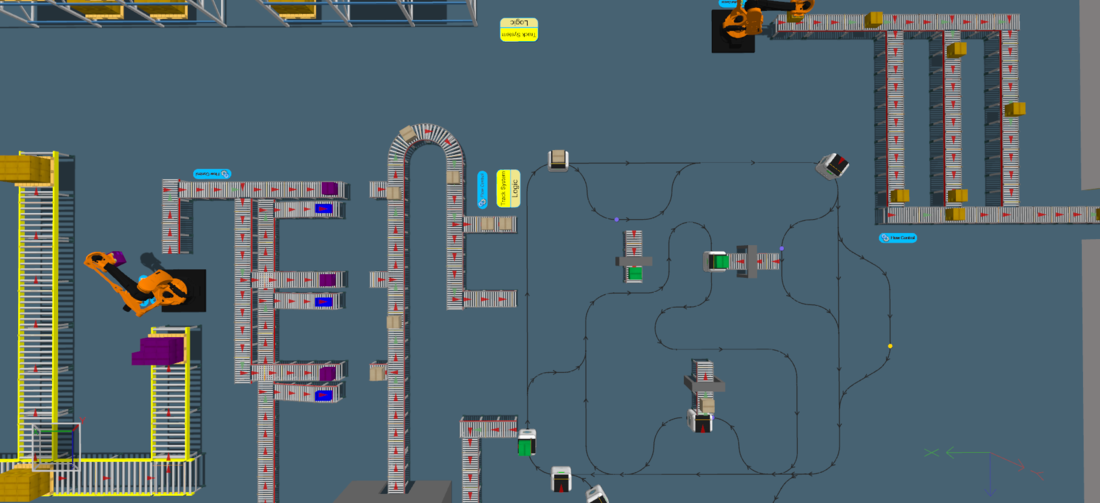

An extensive range of library componentsSimulations can be developed from an extensive range of library components or developed from completely custom libraries, models and CAD. The user has complete control over how simulations are created as well as the development of custom libraries to suit individual company user scenarios and products. As Emulate3D Simulator has been developed for the automation and materials industry, there is a large variety of pre built simulations modules and components that allow for the rapid creation of most simulation scenarios. These components can be snapped together and allow for a user interface that provides fast, easy and flexible simulation model creation. |  |

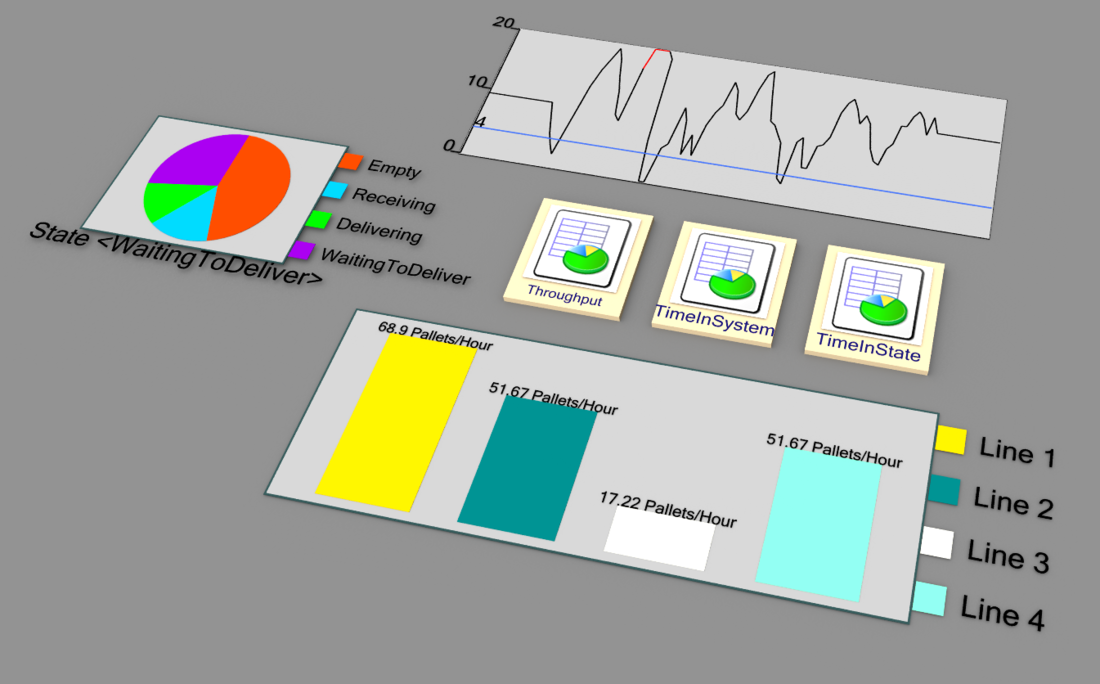

| Reduce the risks associated with your project decisionsEmulate3D Simulator helps you to analyze system throughput, identify bottlenecks, dimension layouts accurately, and test out different operational modes to increase your understanding of how a system responds to changes. Bring “what if” scenarios to life and compare results to select the best configuration and functional parameters for your requirements. Simulation helps to determine “the best” solution, but also leads to robust models that provide a complete understanding of system behaviour across a broad range of operational scenarios. |

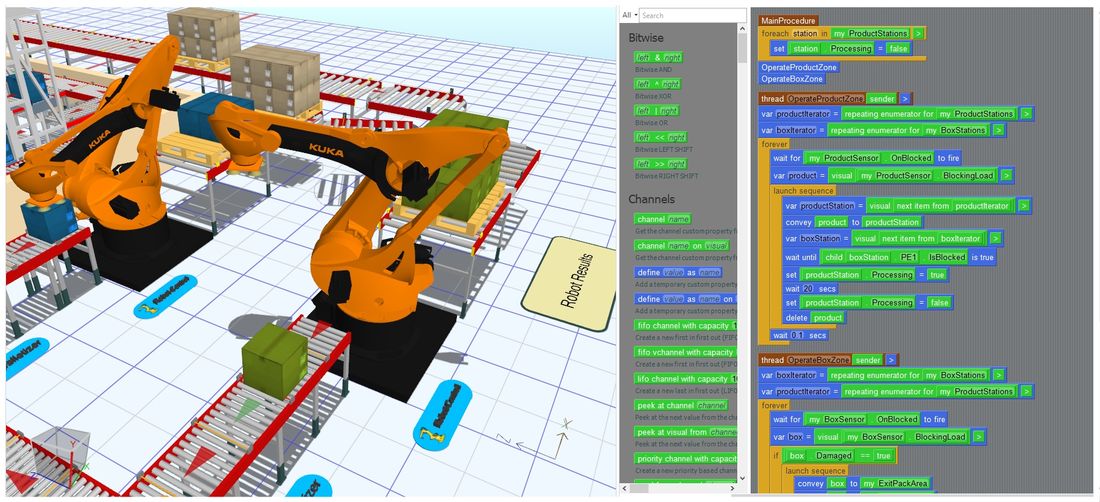

Build Robust Models Quickly with Sim3DThe Emulate3D Simulator modeling framework enables users to create model layouts quickly using standard drag and drop catalog components. Once the system layout is complete, the default operational logic of each element can be modified by overlaying system-specific logic which represents the business rules of your model. A wide variety of CAD formats can be imported to enhance the visual aspect of the model, or to help with the layout. Users can create their own company-specific catalogs and equipment items with behaviors defined by custom logic, and which may incorporate imported CAD. |  |

| Designed for a Wide Range of UsersEmulate3D Simulator has been designed for a Wide Range of Users across the entire automation and materials handling industries. Emulate3D Simulator users can add project-specific operational logic in several ways, reflecting the diverse user base of Emulate3D technology across many industries. Power users benefit from the integration of Microsoft’s Visual Studio C# editor and debugger as a productive and familiar work environment, which accelerates their workflow. Other users appreciate the straightforward drag and drop logic editor, and those more used to working with PLCs can even create logic with the internal ladder logic editor. |

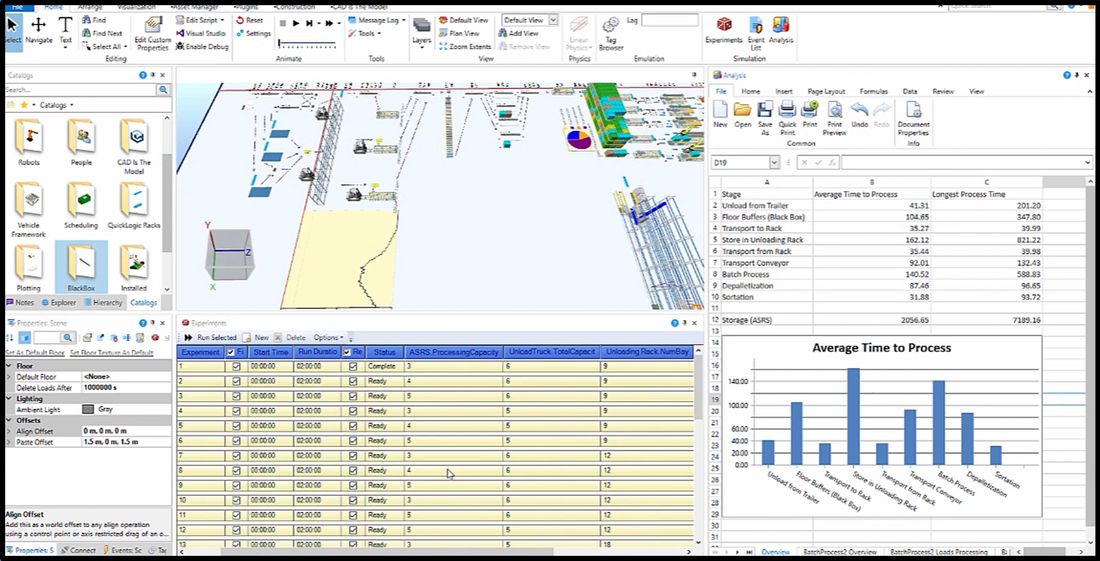

Set up 'experiments' and 'what-if' scenario'sOnce a simulation model has been created, users can set up 'experiments' and 'what-if' scenario's to understand how the proposed layout performs under a range of production scenarios. These scenario's can be queued in a set and forget process that allows the user to walk away while Emulate3D Simulator runs each scenario. Data collected in Emulate3D Simulator can be reviewed and analysed via the internal Analysis Tools. All Data collected can also be exported to packages such as MS Excel where the full feature list of those products can be utilised and exploited. |  |